RC Cleaner -

The ideal precision cleaning unit for electronics, optics and precision engineering

with:

.

.

Application:

The precision cleaning unit RC Cleaner is ideal for precision cleaning and vapour degreasing or pure particle removal of electronic components, glass, metal or plastic parts and implants.

Individual customized solutions are available based on the size of the components and the desired throughput.

RC 250 A RC 350M

Precision cleaning media

The 3M Novec Engineered Fluids (hydro-fluor-ether, short HFE) have been developed for the cleaning of sensitive materials in replacement of CFC, HCFC and other solvents. The HFE are non-flammable fluids predestined for a precision cleaning and a drying without traces. The HFE is able to open new opportunities for the precision cleaning in the application areas of electronics, mechanics and optics.

The use of HFE is authorized by the German law under the restriction that the mass flow doesn’t exceed 30 grams per hour. The precision cleaning systems RC CLEANER on the basis of co-solvent / HFE decrease the emissions under the authorized level of the German law of 30 grams per hour.

RC Cleaner 500

RC Cleaner 500

RC 470

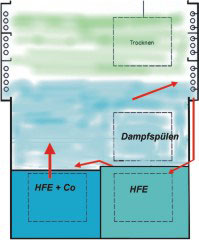

Principle:

The cleaning of products takes place in an immersion cleaning

unit using  and a co-solvent.

and a co-solvent.

A well-balanced heating and cooling system in conjunction with ultrasonic cleaning, comfortable controls, etc. guarantee high process reliability and cleaning quality.

The process is completed by continuous distillation and reprocessing of the![]() Novec (HFE) Thanks to these features, the system is able to clean off ultrafine particles in a wide range of applications, making this unit interesting for a great number of application areas.

Novec (HFE) Thanks to these features, the system is able to clean off ultrafine particles in a wide range of applications, making this unit interesting for a great number of application areas.

schematic diagram

| Basic configuration |

Options |

|

|

Änderungen vorbehalten!