Pharma Cleaning system

Series 28-PH

Riebesam pharmaceutical cleaning, disinfection, and drying systems are subject to the strictest controls and the most meticulous manufacturing processes.

Series 28 represents the entry point into large-chamber cleaning systems. It offers two washing levels with integral loading trolleys and can be operated either in stacked mode or with telescopic extension. For loading with a wide variety of wash items, modular operation is available, allowing up to four different washing-rack modules to be used – each optimized for the specific application.

Features of the basic unit:

Width | 1160 mm |

Depth | 918 mm |

Height | 1856 mm + 20mm/-0 |

Chamber volume | 685 l |

- Construction, manufacturing, and implementation in compliance with cGMP, GAMP, and FDA guidelines

- Pharmaceutical-grade stainless steel AISI 316L (1.4404 / 1.4435)

- Dead-leg-free washing chamber design with rounded corners, electropolished (mirror finish)

- Pharmaceutical-grade stainless steel circulation pumps (e.g., Hilge) with self-draining capability

- Diaphragm valves (e.g., Gemü, Sisto)

- Orbitally welded piping system with TriClamp or sterile flange connections (e.g., Neumo, Südmo)

- All non-stainless-steel product-contacting parts FDA-approved

- High-performance drying with terminal H13 filter

- Control via state-of-the-art PLC (e.g., Siemens S7-1200)

- Data recording in compliance with 21 CFR Part 11

- Comprehensive documentation

- IQ/OQ/PQ support including FAT (Factory Acceptance Test) and SAT (Site Acceptance Test)

Details

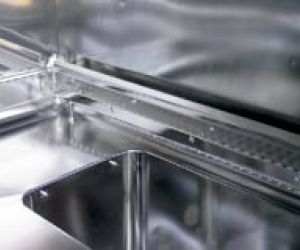

Wash chamber

Electropolished wash chamber with rounded corners (dead-space-free)

Diaphragm valve

Diaphragm valves with TriClamp connections for WFI (Water for Injection) and PW (Purified Water)

Circulation pump

Pharmaceutical-grade circulation pump and orbitally welded piping with TriClamp connections

Rear view

Rear view with orbitally welded piping and diaphragm valve

The following versions are available:

- Pass-through unit (two-door) with hinged doors

- Pass-through unit (two-door) with lift doors

- Single-door unit with hinged door

- Single-door unit with lift door

All-in-One-Design:

- Space-optimized machine housing

- Cleaning agents, components, and all connections are integrated into the housing of the cleaning system and can be easily accessed via a maintenance access point.

- The system can be installed flush against the wall and seamlessly aligned with other equipment within the room layout.

The modular design ensures optimal implementation of your specifications (URS) at all times.